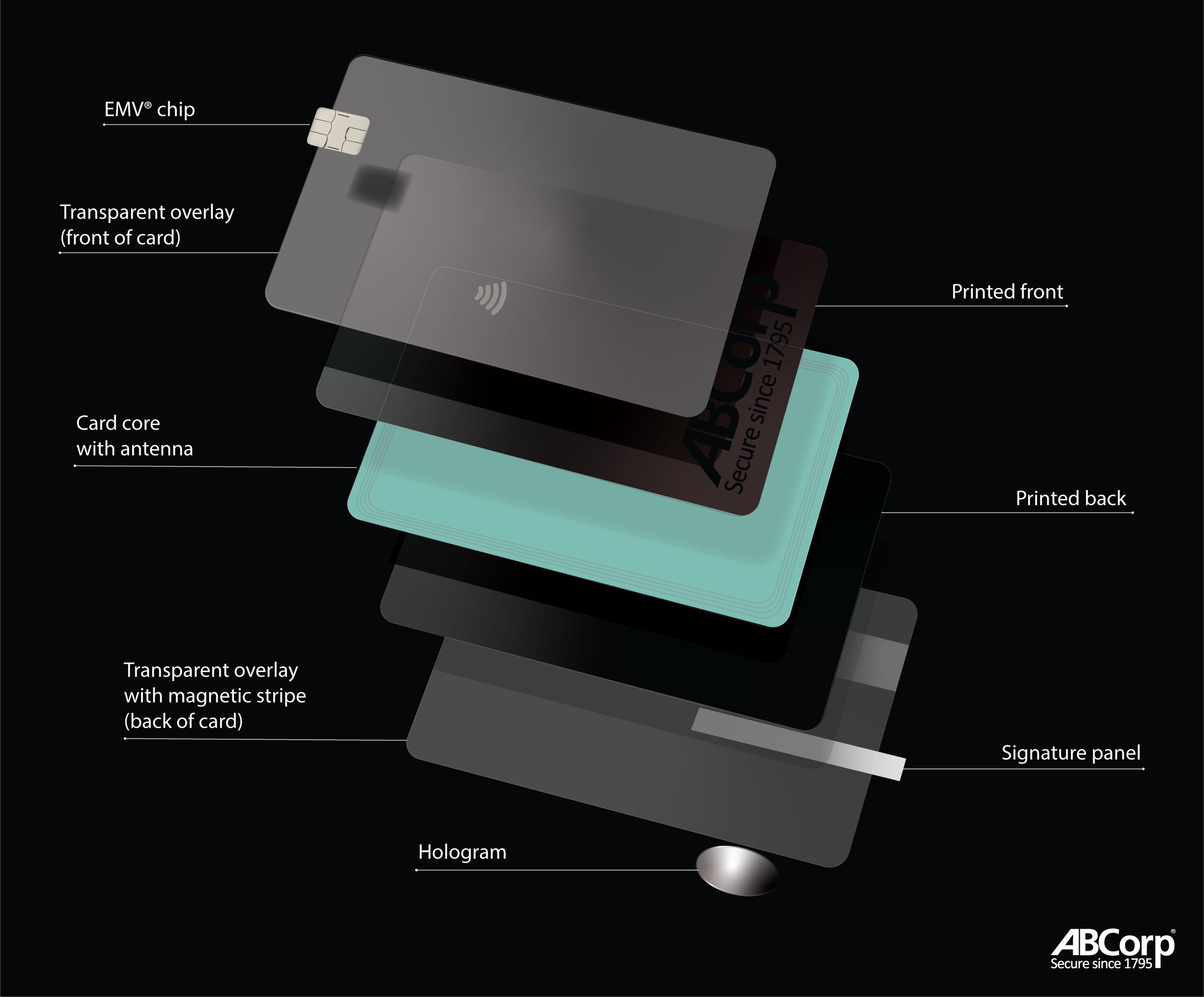

Payment cards are critical tools for facilitating commerce, and credit card and debit card manufacturing ensures their reliable availability. And while payment cards may appear to be unassuming pieces of plastic, they contain a surprising number of precision-engineered layered components that come together to create secure, durable, and multi-functional financial instruments.

8 components of payment card manufacturing construction

For those seeking a deeper understanding of payment card manufacturing, it helps to peel back the layers of card construction and understand the purpose of each component. This blog examines eight components that come together to form financial cards and the role that each layer plays.

1. Card core with antenna

Let’s start from the inside out. The core of a payment card is its central body, giving it rigidity and durability. It can be made of a variety of substrates, including PVC and metal. Plastic and plastic alternatives may be colored to the credit card company’s specifications to produce a custom “color core” design. The core layer of contactless cards will contain an antenna made of copper or aluminum that enables near field communication (NFC) with point-of-sale (POS) devices, allowing contactless payments. In some instances, the antenna may reside on the EMV® chip via an antenna-on-module design.

2. Printed front

The front surface of a debit or credit card may include card branding, the card network logo, personal account information (cardholder name, account number, expiration date, etc.), and printed design elements. The printed front of a payment card is typically created by one of two printing methods. The first, lithographic or offset printing, is the go-to printing method for high‐volume, high‐quality color. It allows a high degree of customization for ink colors and bespoke printing techniques like screen printing. The second option, digital printing, facilitates quicker setup, faster turnaround times, and shorter printing runs. This front layer is typically printed on PVC or plastic alternatives and can be dyed to match a bespoke color scheme.

3. Printed back

The printed back of the payment card includes additional printed information such as the CVV/CVC code, the issuer’s contact information, and general terms and conditions. The back of the card also provides an opportunity to add additional brand and design elements. Back printing must align carefully so that the magnetic stripe and signature panel can be correctly positioned during subsequent manufacturing steps. As with the front-of-card, this layer is typically made from PVC or plastic alternatives and can be dyed to customer specifications.

4. Transparent overlay (front of card)

A protective barrier is formed around the front of the card with transparent plastic overlay through a lamination process in which intense heat and pressure are applied to create a secure bond. This lamination helps protect the card from abrasion, moisture, bending, and tampering. Overlay can be applied with a variety of finishes including gloss, matte, or satin.

5. Transparent overlay with magnetic stripe (back of card)

This component refers to the protective lamination that covers the back of the card and sometimes contains the magnetic stripe. The magnetic stripe itself stores data in distinct tracks that card readers can access when the card is swiped. Post-lamination card construction elements that are hot stamped (holograms and signature panels) are applied directly to the back overlay.

6. Hologram

Payment card production services can also include a hologram, which is a visual security feature designed to combat counterfeiting. Holograms are small, reflective, and multi-level images constructed with holographic foil that changes appearance based on the viewing angle. Holograms are affixed to a card via a post-lamination process called hot stamping, a high-temperature transfer of the secure holographic foil to the card. Most commonly used to indicate a card network’s brand mark (for example, Mastercard’s circles or Visa’s dove), holograms can also be employed for applying artistic design elements that create a unique and premium appearance.

7. Signature panel

While signature panels are now optional on most credit cards, it is a design element that gives cardholders an opportunity to add a personal element. Using the heat and pressure of a hot stamping process, signature panels are applied to the back of the card post-lamination and usually placed just below the magnetic stripe. Signature panels can be customized with bespoke colors, creating a visually appealing spot for cardholders to apply their signature.

8. EMV chip

EMV is a technical standard for payment cards and an abbreviation for the organizations that developed the standard (Europay, Mastercard, and Visa). Commonly referred to as chip cards or smart cards, payment cards with embedded EMV chips provide an extra layer of security in which data is stored on a small, embedded integrated circuit module (microprocessor chip) that is read by physical terminals when the chip card is inserted. A chip card payment is authenticated using a one-time security code that is unique to each transaction. Because a one-time code is created every time, the data cannot be used to clone the payment card.

An EMV chip is the ultimate authenticator of a card payments and plays a fundamental role in preventing fraud and the use of counterfeit cards. Card manufacturing companies, like ABCorp, create EMV chip cards through a process called milling and embedding, in which a precise cavity is carved into payment cards that fit the specifications of the accompanying chip. Chips are then embedded in a high-speed process that bonds them securely to the payment card and embedded antenna.

The role of a card production facility in payment card manufacturing

A payment card manufacturing company brings these layers together through an intricate process of printing, gathering, laminating, hot stamping, and milling and embedding. All while ensuring the highest level of quality and security standards throughout. These eight components illustrate why payment cards are more than just “plastic with numbers.” For anyone researching debit card and credit card manufacturing company practices or comparing providers of card production services, understanding the basics of payment card construction is a must.

To learn more about ABCorp’s payment card manufacturing solutions, contact our team today!