What’s the Real Difference and Which One Is Right for You?

If you’re comparing injection molding vs 3D printing/additive manufacturing, you’re not alone. These two methods dominate modern production, but they solve completely different problems. And for many product teams and engineers, choosing between them feels like choosing between speed and scale, cost and complexity, today’s needs and future flexibility.

The truth?

They’re both powerful, but they’re not built for the same thing.

In a world where design cycles are shrinking, products are hyper‑customized, and teams need to move faster while staying cost‑conscious, additive manufacturing, often delivered through specialized 3D printing services, is stepping into a new role. It’s no longer just about prototyping; it’s about real, production‑ready manufacturing.

Below is a breakdown of how injection molding and additive manufacturing work, and why more manufacturers are turning to industrial 3D printing services for the agility, speed, and complexity that molded parts can’t match.

How Injection Molding Works

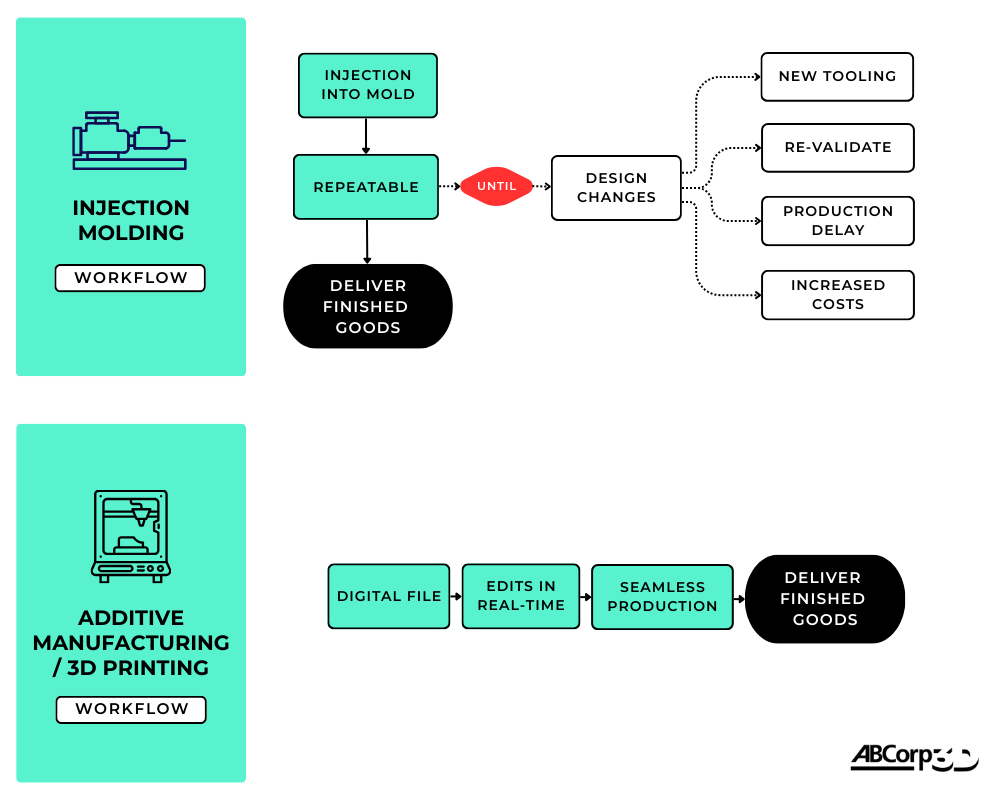

Think of injection molding as the legacy workhorse of manufacturing. It’s been around for decades, there’s deep familiarity with it, and it’s excellent at one thing: making the same part, repeatedly, at high volume. But the path to get there? Unfortunately, it’s not seamless.

1. You Need a Mold…and It’ll Cost You

Whether aluminum or steel, tooling costs add up fast. For many projects, you can’t even start production until you’ve spent thousands, or tens of thousands, building the mold. This makes injection molding less practical for teams that need flexibility or are exploring early‑stage production before committing to full‑scale tooling.

2. Every Design Change Pauses Production

With injection molding, it’s repeatable… until it isn’t.

New design? Requires new tooling. New tooling? Requires new validation. New validation? New delays and higher costs. What should be a simple design tweak becomes a multi‑week (sometimes multi‑month) detour. This is why many teams explore rapid prototyping services or a rapid prototyping service bureau before locking in a final molded design.

3. Complexity = Cost

Curves, hollow structures, internal channels, lattice patterns, really anything beyond simple geometry, become difficult, expensive, or impossible with molding unless you add specialized inserts or multi‑part tooling.

Additive Manufacturing: Fast, Lean, Adaptable Production

Additive manufacturing doesn’t rely on molds at all. Instead, parts are built layer‑by‑layer directly from a digital file, a process central to modern industrial additive manufacturing systems. This shift from physical tooling to digital workflows fundamentally changes how products are designed and produced. Many companies access this capability through a 3D printing or rapid prototyping service bureau rather than investing in equipment up front.

1. No Molds. No Tooling. No Upfront Investment.

Your CAD file becomes your production tool. With 3D printing production services, teams skip weeks of waiting and move straight into manufacturing.

2. Design Changes Happen in Real Time

Need to strengthen a section? Update a tolerance? Add a logo? Improve ergonomics?

You simply update the file and print again. No downtime. No unexpected tooling costs. This is why MJF (multi jet fusion) 3D printing services and other industrial additive technologies are widely used for both prototyping and end‑use production.

3. Complexity Is Free

Where molding penalizes complexity, additive manufacturing embraces it.

Think:

- Curved geometries

- Lightweight lattice structures

- Custom‑fit forms

- Internal channels

- One‑piece assemblies

If you can design it, a qualified metal additive manufacturing service or polymer printing provider can likely produce it.

4. Production Becomes Faster, Leaner, and More Adaptable

Additive manufacturing isn’t here to replace molding for million‑unit runs, but it excels in low-to-mid-volume production, bridge manufacturing, and the production of customized parts. Many manufacturers rely on large‑scale 3D printing services or large 3D printing companies to support these needs without long lead times.

Injection Molding vs Additive Manufacturing: A Side‑by‑Side Comparison

| Category | Injection Molding | Additive Manufacturing |

|---|---|---|

| Upfront Costs | High $$$ (Tooling Required) |

Low $ (No Moldes) |

| Speed to First Part | Weeks to Months | Hours to Days |

| Design Flexibility | Low | Very High |

| Cost Per Part | Low at Mass Scale | Consistent at low-mid volumes |

| Best For | Millions of Identical Parts | Iterations, Custom Parts, Small-Mid Runs, Complex, Geometries |

| Adaptability | Slow | Instant |

Where Additive Manufacturing Truly Shines

This is where additive manufacturing pulls ahead, not because injection molding is “bad,” but because AM solves the problems modern manufacturers actually face.

1. When You Need to Move Fast

Product cycles no longer follow 12–24-month timelines. Teams need to test, iterate, and launch quickly. Rapid prototyping 3D printing allow companies to

design → produce → test → refine without pausing for tooling.

2. When Your Part Needs Complexity

Lightweighting, texturing, hollow cavities, or consolidating multi‑part assemblies into one. Additive manufacturing allows what molding restricts.

3. When Volumes Don’t Justify Tooling

You may not need a million parts. You may need 200, 2,000, or 20,000. That’s where industrial 3D printing services become cost‑effective and significantly lower‑risk.

4. When You Need Bridge Manufacturing

Waiting for tooling or mold revisions can stall production. Rapid prototyping and 3D printing services fill the gap, keeping projects moving while permanent tooling is finalized. For many manufacturers, this complementary role is the primary reason they adopt additive manufacturing.

So, Which Should You Choose?

The fundamental shift in manufacturing isn’t choosing additive manufacturing instead of injection molding, it’s understanding where each belongs in a modern workflow.

For a more detailed breakdown, get our ebook where we explore how additive manufacturing delivers the most significant advantages. But in short, here’s the simplest way to decide:

- If you need ultra‑high volumes (hundreds of thousands to millions), injection molding is still your best option.

- If you need speed, customization, design iteration, or low‑to‑mid production volumes, a trusted 3D printing service bureau offers flexibility that molding can’t.

- If you need a bridge between prototyping and molded production, additive manufacturing seamlessly fills that gap.

In short, additive manufacturing shines where agility, precision, and adaptability matter most.

Let’s Connect

Manufacturing leaders win by adapting early.